Advancing Operational Uptime and Equipment Availability

In the dynamic world of industrial and manufacturing sectors, machine uptime and availability are fundamental concepts that shape productivity and operational efficiency. A deep understanding of these terms, coupled with strategic measures for enhancement, can lead to substantial benefits for businesses aspiring to excel.

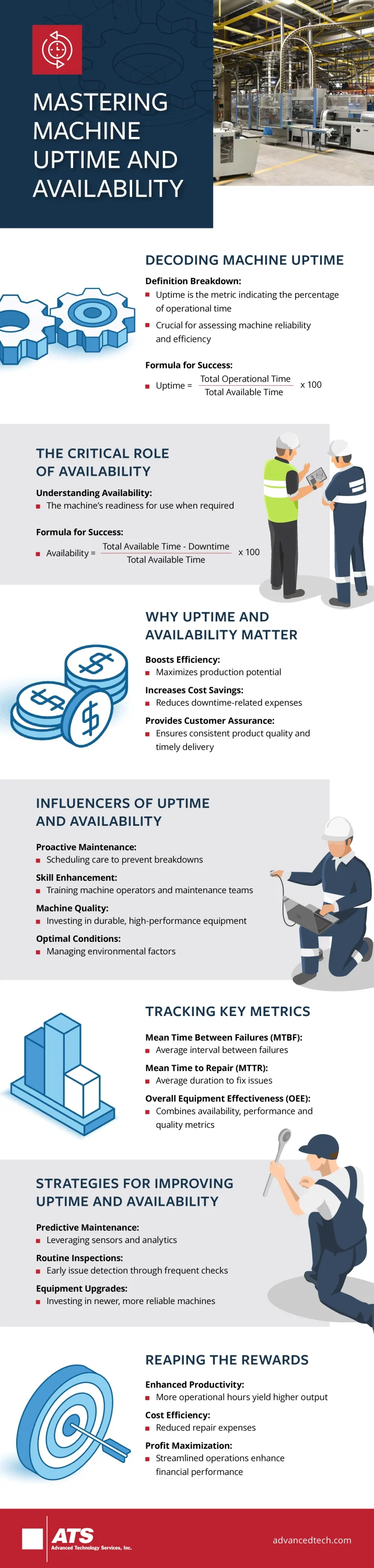

Machine uptime refers to the percentage of time that machinery is fully operational and available for use. This crucial metric serves as an indicator of the reliability and efficiency of equipment. High machine uptime signifies that machinery is functioning without interruption, allowing for maximized production output. Achieving such uptime requires diligent maintenance practices, skilled operators, and robust machinery.

Availability, however, encompasses more than just operational time. It includes the readiness of machinery for use, discounting any periods of downtime. This aspect is vital because even if a machine isn’t actively employed, it must be poised for action to avert bottlenecks in production processes. Thus, availability integrates uptime with the readiness of equipment, ensuring smooth operational transitions.

The importance of machine health monitoring cannot be overstated. High uptime ensures maximum productivity by reducing idle machine time. This efficiency directly impacts the bottom line, minimizing costs associated with repairs, maintenance, and downtime. Moreover, consistent machine performance fosters timely deliveries, ensuring quality standards are met and enhancing overall customer satisfaction.

Several factors influence machine uptime and availability. Preventive maintenance stands out as one of the most critical aspects, involving regular and scheduled maintenance to prevent unexpected failures. This proactive approach helps identify potential issues before they escalate into major problems, ensuring that machinery remains operational and available. The training and skill level of operators and maintenance personnel are equally important; well-trained staff can quickly diagnose and address issues, maintaining smooth operations.

The quality of the equipment itself is another crucial factor. Investing in high-quality, reliable machines can greatly enhance uptime and availability. Such machines are less prone to breakdowns and often feature advanced technologies that facilitate maintenance and monitoring. Additionally, environmental conditions such as temperature, humidity, and cleanliness can significantly influence machine performance. Properly managing these conditions is critical for maintaining optimal operating environments, thereby improving uptime.

To effectively measure machine uptime, key metrics like Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) are commonly utilized. MTBF provides insights into the average time between equipment failures, while MTTR indicates the average time needed to repair and restore equipment to operational status, reflecting the effectiveness of maintenance processes.

Enhancing machine uptime and availability involves the adoption of advanced strategies like predictive maintenance. This innovative approach leverages sensors and data analytics to foresee potential failures before they occur, allowing for timely interventions. Regular inspections and upgrading equipment to newer, more reliable models are also effective tactics for improving uptime.

In summary, mastering machine uptime and availability is essential for maintaining efficient and cost-effective operations in any industrial environment. By focusing on preventive and predictive maintenance, investing in high-quality equipment, and ensuring a well-trained workforce, businesses can significantly boost productivity and enhance customer satisfaction.

For more detailed insights on machine uptime and availability, consult the accompanying graphic.

What Happens After Your Security Alarm Goes Off?

What Happens After Your Security Alarm Goes Off?  How Make-Good Services Ensure Smooth Lease Transitions and Compliance

How Make-Good Services Ensure Smooth Lease Transitions and Compliance  The Shift from Concept to Real-World 3D Build Projects

The Shift from Concept to Real-World 3D Build Projects  Effortless Office Moves in Melbourne

Effortless Office Moves in Melbourne  SEBI’s Latest Regulations for Investment Advisory Services in India

SEBI’s Latest Regulations for Investment Advisory Services in India  Exploring the Most Effective Business Services for Entrepreneurs

Exploring the Most Effective Business Services for Entrepreneurs  The Evolution of Industry: From the Industrial Revolution to the Age of Automation

The Evolution of Industry: From the Industrial Revolution to the Age of Automation