The Evolution of Industry: From the Industrial Revolution to the Age of Automation

The story of industry is one of continuous transformation, punctuated by groundbreaking innovations and shifts in how goods are produced, distributed, and consumed. From the mechanized factories of the 18th century to the smart factories and automation technologies of today, industry has been the driving force behind economic growth, technological progress, and societal change. The industrial age reshaped not only the landscape of economies but also the very fabric of human existence. As we move into the 21st century, industry finds itself at the crossroads of a new era, one defined by automation, artificial intelligence (AI), and sustainable practices. This article examines the trajectory of industry, its impact on society, and how it is poised for its next great leap.

The Industrial Revolution: The Birth of Modern Industry

The roots of modern industry can be traced back to the late 18th century, when the Industrial Revolution began to take shape in Great Britain. Prior to this, most goods were produced through manual labor or in small-scale, artisanal workshops. The shift to mechanized production marked the dawn of a new era. At the heart of the Industrial Revolution were innovations such as the steam engine, pioneered by James Watt, and the mechanization of textile production. These breakthroughs allowed businesses to increase production efficiency, reduce labor costs, and expand their reach.

The widespread adoption of the steam engine revolutionized industries beyond textiles, particularly in mining, transportation, and manufacturing. The ability to power machines with steam made it possible to operate factories in locations far from water sources, which had previously been the primary source of energy. As steam-powered locomotives and ships became more common, transportation networks expanded, and the movement of goods became faster and more efficient. This interconnectedness paved the way for global trade and helped usher in the rise of consumerism.

As industrialization spread across Europe and North America, new industries began to emerge. The rise of factories led to a shift from agrarian economies to urbanized societies, with people flocking to cities in search of work. This demographic shift marked the beginning of the modern era, where the rhythm of life became governed not by the seasons or agricultural cycles, but by the pulse of the factory and the clock.

The Rise of Mass Production: The Fordian Model

The early 20th century witnessed further advancements in industry, particularly in the area of mass production. One of the most significant developments was Henry Ford’s introduction of the assembly line in 1913. Ford’s decision to use an assembly line to produce the Model T revolutionized the automotive industry and had profound implications for manufacturing in general. Instead of relying on a team of skilled laborers to assemble a product from start to finish, Ford’s assembly line allowed workers to perform specialized tasks, each contributing to a part of the process. This dramatically reduced the time it took to produce each vehicle, making the Model T affordable to the masses.

Ford’s innovations had far-reaching consequences, not just for the automotive industry but for industrial production as a whole. The efficiency of mass production allowed for the creation of standardized products at scale, which helped fuel the growth of consumer markets. This period, often referred to as the age of standardization, was marked by an increased availability of goods, from automobiles to household appliances to clothing.

The expansion of mass production also coincided with the growth of large corporations and the rise of industrial giants. Companies like General Motors, Coca-Cola, and General Electric became symbols of American industrial might. However, while mass production brought prosperity to many, it also brought about new challenges, including labor exploitation, poor working conditions, and the rise of unions that fought for better wages and rights for workers.

The Digital Revolution: The Shift from Mechanical to Digital Industry

By the latter half of the 20th century, another revolution was underway—one that would fundamentally change the nature of industry: the digital revolution. The introduction of computers and automation into industrial processes in the 1970s and 1980s began to alter manufacturing once again. Rather than relying solely on mechanical systems and human labor, industries began to incorporate computers to improve precision, speed, and control.

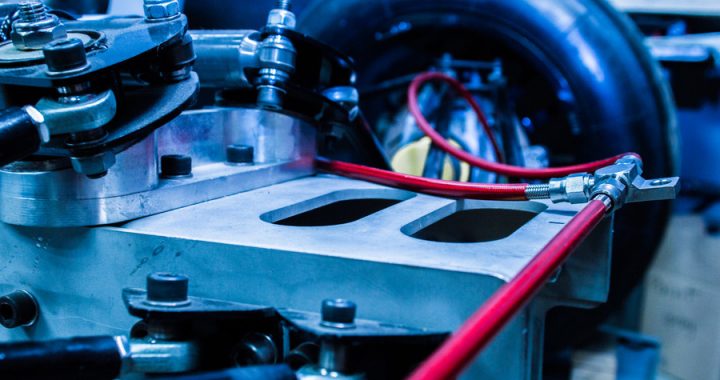

This shift led to the development of computer numerical control (CNC) machines and robotics in manufacturing, allowing factories to produce goods with greater accuracy and less human intervention. At the same time, the rise of information technology and the internet enabled businesses to streamline their operations, manage supply chains more efficiently, and reach global markets in ways that had been unimaginable just a few decades earlier.

The information age brought with it the rise of industries centered around technology itself. Companies such as Microsoft, Apple, and Google became not just corporate entities but cultural icons. The proliferation of personal computers and the internet transformed the way we live, work, and communicate. In industries such as retail, the digital revolution gave rise to e-commerce, which disrupted traditional brick-and-mortar business models and changed consumer behavior forever.

The advent of enterprise resource planning (ERP) systems and supply chain management software helped businesses optimize their operations, reducing costs and improving efficiency. This era of digitalization also saw the rise of globalization, as businesses increasingly operated across borders, sourcing raw materials, outsourcing labor, and selling products in far-flung markets.

Industry 4.0: The Age of Automation and Smart Manufacturing

Today, we are entering the era of Industry 4.0, a term coined to describe the next wave of industrial transformation. At its core, Industry 4.0 is characterized by the integration of cyber-physical systems, Internet of Things (IoT), artificial intelligence (AI), machine learning, and big data into manufacturing processes. These technologies enable factories to operate more autonomously, with machines communicating with one another in real-time to monitor performance, detect issues, and optimize production without human intervention.

One of the most promising aspects of Industry 4.0 is the development of smart factories, where connected devices and sensors gather data from every stage of the production process. This data is then analyzed using AI and machine learning algorithms, allowing for predictive maintenance, real-time decision-making, and continuous optimization of operations. For example, a factory could automatically adjust production schedules based on real-time demand data, or machines could self-repair when an issue is detected, minimizing downtime.

The rise of automation has also led to the use of robotics in industries ranging from automotive to healthcare. Robots now perform tasks ranging from assembly to packaging, with increasing levels of dexterity and precision. These advancements are reshaping the labor market, as some jobs are replaced by machines while new, more specialized roles emerge.

However, while Industry 4.0 promises increased efficiency and productivity, it also presents new challenges. One of the most pressing concerns is the potential for widespread job displacement as automation takes over more tasks traditionally performed by humans. The growing reliance on AI and machine learning also raises ethical questions about data privacy, security, and the role of human decision-making in automated processes.

The Future of Industry: Sustainability and the Green Revolution

As industry continues to evolve, sustainability is emerging as a central concern. With the world facing climate change, resource depletion, and environmental degradation, industries are being called upon to adopt greener, more sustainable practices. In response, companies are turning to renewable energy, circular economies, and green manufacturing technologies to reduce their environmental impact.

Tesla has led the way in transforming the automotive industry with its focus on electric vehicles, while companies in sectors like fashion, agriculture, and construction are also embracing sustainable practices. For instance, 3D printing is being used to reduce waste in manufacturing, while the rise of sustainable supply chains seeks to minimize environmental harm at every stage of production.

As industries continue to embrace sustainability, they must also focus on social responsibility, ensuring that their operations are not only environmentally sound but also ethically responsible. This includes fair labor practices, community engagement, and contributing to the broader goal of reducing global inequality.

Conclusion: The Industrial Landscape of Tomorrow

The evolution of industry, from the steam-powered factories of the Industrial Revolution to the smart, connected manufacturing systems of today, is a testament to human ingenuity and the drive for progress. As we look toward the future, the industrial landscape will continue to be shaped by technological advancements, automation, and a growing emphasis on sustainability.

In this new era, industries must navigate the delicate balance between efficiency and ethics, automation and employment, growth and environmental stewardship. The challenges are immense, but so are the opportunities. The future of industry lies not just in producing goods faster or cheaper but in creating value that benefits society as a whole—an enterprise not just for profit, but for progress.

Winning Approaches: Top Marketing Strategies for Success in the Business Industry

Winning Approaches: Top Marketing Strategies for Success in the Business Industry  Here’s How Wireline Companies Are Helping The Oil Industry!

Here’s How Wireline Companies Are Helping The Oil Industry!  Choosing the proper Industrial Supplies for Quality Management

Choosing the proper Industrial Supplies for Quality Management  Fertilizer Production Displays Negative Effects On Phosphate Industry Workers

Fertilizer Production Displays Negative Effects On Phosphate Industry Workers  Maximizing The need for Your Industrial Equipment

Maximizing The need for Your Industrial Equipment  Florida Phosphate Industry Officials, Poor Ecological Stewards?

Florida Phosphate Industry Officials, Poor Ecological Stewards?  How Make-Good Services Ensure Smooth Lease Transitions and Compliance

How Make-Good Services Ensure Smooth Lease Transitions and Compliance  The Evolution of Industry: From the Industrial Revolution to the Age of Automation

The Evolution of Industry: From the Industrial Revolution to the Age of Automation  Effortless Office Moves in Melbourne

Effortless Office Moves in Melbourne  The Art of Management: Leading with Vision and Strategy

The Art of Management: Leading with Vision and Strategy